Products

ENiCrMo-3

Chemical Composition Of Deposited Metal(%)

|

Pilot Projects |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

Cu |

Fe |

Nb+Ta |

|

Guaranteed Value |

≤0.10 |

≤2.0 |

≤0.80 |

≤0.015 |

≤0.020 |

≥55.0 |

20.0-23.0 |

8.0-10.0 |

≤0.5 |

≤7.0 |

3.0-4.2 |

|

Example Value |

0.017 |

0.50 |

0.35 |

0.010 |

0.005 |

60 |

21.00 |

8.50 |

0.040 |

5.20 |

3.30 |

Purpose:

It is mainly used for ni-cr-mo alloy welding, especially for UNS N06625 alloy and other steel and ni-cr-mo alloy composite steel welding and surfacing welding. It can also be used for Ni9% steel welding at low temperature. Compared with UNS N06625 alloy, the weld metal has corrosion resistance and can work at 540℃.

Features:

ENiCrMo-3 has excellent plasticity, toughness and crack resistance. The weld metal has high strength and corrosion resistance at room and high temperature.

Points to note:

1. The electrode must be baked at 300-350℃ for 1 hour before welding.

2. Before welding must be removed from the welding rust, oil, moisture and other impurities.

3. When welding, adopt small current multi-layer welding as far as possible, adopt short arc

welding.

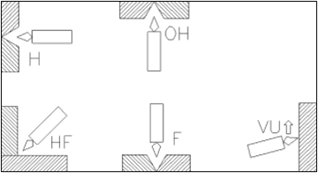

Welding position: