Products

E7018 -1/J506Fe-1

Chemical Composition Of Deposited Metal(%)

|

Pilot Projects |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Guaranteed Value |

≤0.15 |

≤1.60 |

≤0.90 |

≤0.035 |

≤0.035 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Example Value |

0.069 |

1.20 |

0.36 |

0.006 |

0.016 |

0.26 |

0.031 |

0.008 |

0.017 |

Purpose:

Suitable for welding carbon steel and low alloy steel structure. Such as Q345, Q345R, etc. .

Features:

J506Fe-1 is an iron powder basic coating low hydrogen potassium electrode. AC, DC dual-use, all-position welding. Due to the addition of more alloy elements, excellent plasticity and low-temperature impact toughness, good welding process performance, arc stability, less spatter, easy slagging, high deposition efficiency, beautiful weld formation.

Points to note:

1. The electrode must be baked at 380 ~ 400℃ for 1H before welding.

2. Before welding must be removed welding rust, oil, moisture and other impurities.

3. Short arc must be used when welding operation, swing range should not be too large, to narrow bead is appropriate.

4. In order to prevent the formation of air holes, arc-starting plate should be used or return method of arc-starting welding.

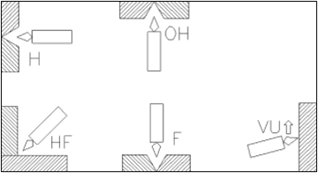

Welding position: